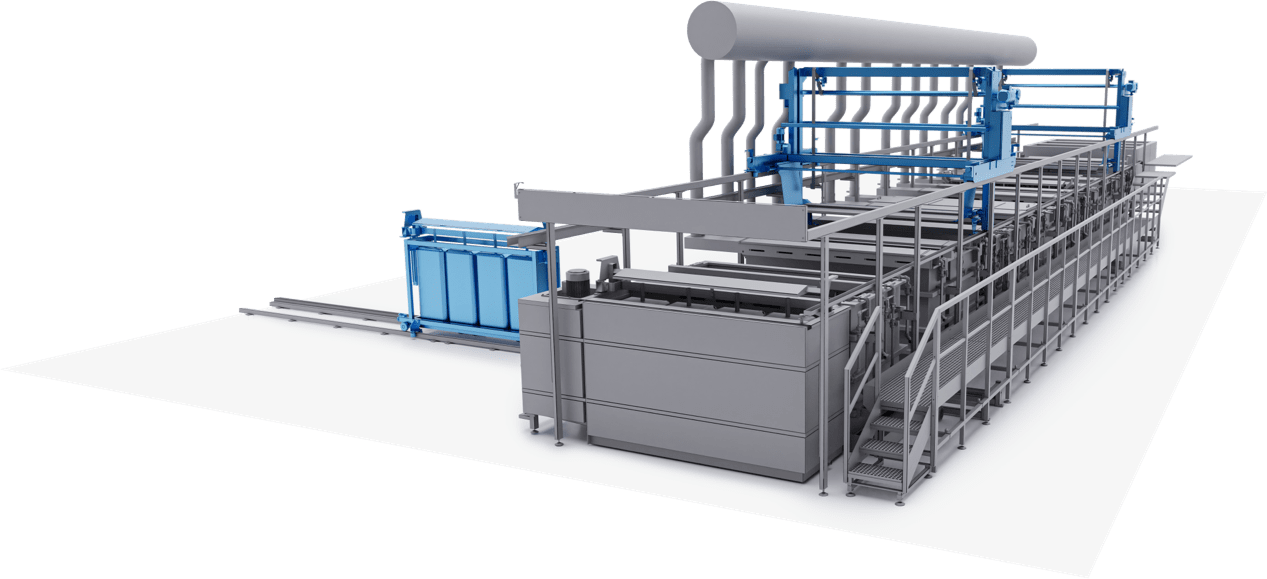

Company’s main activity is designing & erection of new industrial plants along with the development of the automation SW involved, in the field of galvanic/chemical surface treatments.

In the same sector we take care of the revamping of existing installations as well, to turn them into reliable and efficient Lines

We provide quality maintenance and technical assistance services, spare parts supply:

we rely on our multi-year experience, and on a very experienced team of experts and engineers with extensive knowledge in Galvanic Lines Design and Implementation technologies, as well as in special machinery construction (e.g. lifting and handling, oleodynamic and oleopneumatic solutions).

We share with our Customers and their specialty chemical providers the guidelines of a new project, exploring the best design alternatives, in order to proceed with:

plant engineering, structural and mechanical design

automation and electromechanical design

construction

on site installation and start-up

technical support

In case of existing plants needing Partial or Complete Revamping, or new sub-processes integration, Phox Industrial Plants & Automation is available for inspections in order to propose the best technical solution after in-depth analysis and feasibility.

Once in charge of the project, we move forward until its full realization, according to the production requirements of the plant to be modified.

Phox srl integrates the most recent innovations in the trivalent chromium sector into its projects, operating both in the field of completely new systems, as well as in that one - more complex - of the introduction of new technologies in already mature system configurations.

Ask for information AchievementsPhox srl manufactures complete copper-nickel-chrome systems designed to work on carbon steel, stainless steel, Zamak alloys and brass for various sectors such as: automotive, mechanics, taps, accessories.

Ask for information AchievementsPhox srl carries out the tailor-made design of thick chromium technical systems in the delicate sectors of roto-graphics and mechanics.

Ask for information AchievementsThese plants carry out the metallization of the plastic and the subsequent finishing. They operate mainly in the automotive, sanitary and accessories sectors.Phox srl has focused its engineering attention on processes related to the improvements on POP plants,especially on the introduction of Chrome VI - free treatments in the areas of etching and finishing. Phox software handles up to 12 hoists and 20 different sequences on one of its major POP plants.

Ask for information AchievementsIn these legacy heavy treatments, the robustness of Phox equipment and its control system fully demonstrates all its validity and its modernization ability.

Ask for information AchievementsParticular attention is given to the design and construction of rinsing systems with ultrasounds and demi or ultrademi water. These small systems - completely in stainless steel - are used in the final post-galvanic stage of particularly delicate pieces or as preparation for subsequent application of PVD processes.

Ask for information AchievementsThe skills of Phox srl allow the engineering of water flows and the supply of "tailor made" waste water treatment systems to integrate the supplied galvanic systems.

Ask for information AchievementsPhox srl designs and manufactures complete rack and barrel systems for acid and alkaline zink and zinc-nickel.

Ask for information AchievementsThis process is made by Phox both as an intermediate step in the metallization of plastic and as a surface hardening treatment (nickel phosphide).

Ask for information AchievementsFor this sector Phox mainly manufactures manual systems (but not only) based on small tanks, customized to the maximum, for granting operators maximum flexibility, ergonomics and safety during work.

Ask for information AchievementsPlease, compile the below form in order to ask for more information.