Xloader

HOW DOES XLOADER WORK?

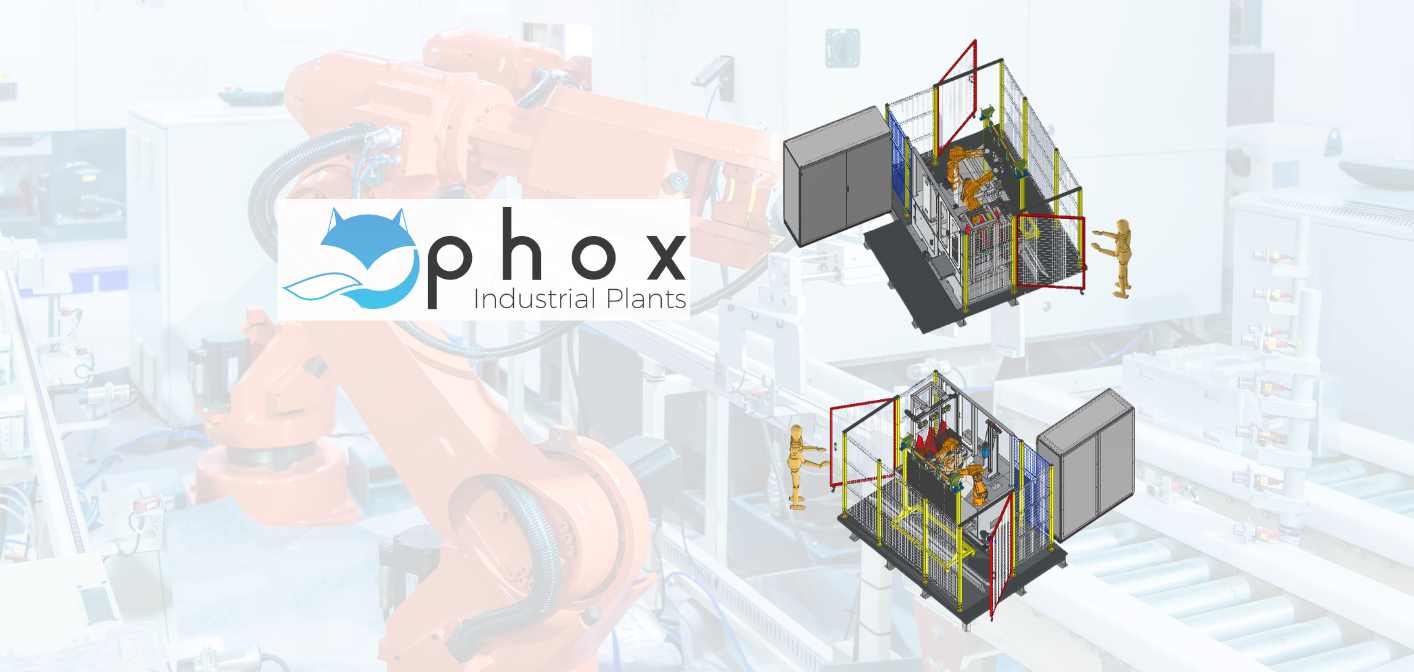

Automatic plating plants move racks through a series of treatment tanks. Typically, articles to be treated are manually loaded onto racks, a time-consuming process prone to human errors. Xloader introduces a fully automated method for this critical phase of the process.

- Integration e Configuration: Xloader is designed for seamless integration into existing plants. Operators place a cart with two empty racks in the designated loading area.

- Automatic Loading: A stack of blister packs containing the articles to be treated is strategically positioned for Xloader's access. This innovative system retrieves articles from the stack and automatically arranges them on the racks, ensuring precise and secure placement.

BENEFITS AND IMPACT

- Increased Efficiency: By eliminating manual loading, Xloader reduces rack preparation time, allowing plants to boost their production capacity.

- Enhanced Quality: Through precise automation, Xloader ensures uniform and secure article placement on racks, enhancing the quality of the plating treatment.

- Cost and Labor Reduction: By automating a process that typically requires intensive manual labor, operational costs are reduced, and operators are relieved from repetitive tasks.

Xloader underscores Phox's commitment to innovation in the industrial automation sector, offering advanced solutions that improve the productivity, quality, and sustainability of plating plants.